The narrative that organisations should seat procurement at the top table for organisations has been ongoing for decades.

https://www.team-canopy.com/post/what-role-for-procurement-seat-at-the-table-or-trusted-advisor

What are your views on this dilemma?

Weismann has a point where he stressed that “essentially states that the pursuit of acknowledgement from the executive suite and the feeling that you are being personally and professionally disrespected if you’re not working at board level, is a fallacy”. He suggests that rather than focusing on the role of procurement in the C-suite, the main way to exert influence is still “the old-fashioned way: through performance”.

Even if you’re not at the table, Nick Verkroost talks about the importance of having a voice at the table – Through the ability to be able to influence stakeholders.

There have also been many publications about the Soft Skills required for procurement professionals. Soft Skills are defined in the oxford dictionary as “personal attributes that enable someone to interact effectively and harmoniously with other people”.

There are so many examples of what these skills are, and correlation is sometimes difficult to achieve generally. The table below is taken from the following publication and is a good general benchmark.

https://www.theforage.com/blog/basics/what-are-soft-skills-definition-and-examples#soft-skills-work

Soft skills are non-technical skills that describe how you work and interact with others. Unlike hard skills, they’re not necessarily something you can learn in a course, like data analytics or programming. Instead, they reflect your communication style, work ethic, and work style.

Do you agree with this? Can soft skills be taught or are we born with them?

Throughout my career, I have wondered why we put a framework / box around these skills and define them as “soft skills”. Are we not doing them a disservice and undermining how hard it is to find people that really excel with these attributes, and underplaying how difficult it is to train them? I always use the frame of “POWER skills” for that reason. What do you call them?

For procurement Professionals soft skills defined by the Chartered Institute of Procurement and Supply are.

What does this all mean? From the top 5 skills listed above and their detailed explanations, I think the key threads are the ability to build relationships through clear communications and collaboration whilst leading the engagement strongly, building successful value outcomes for all stakeholders and suppliers. A bit of a long sentence but captures the essence of above.

However, fundamental to procurement professionals and the most important attribute is the POWER to INFLUENCE!

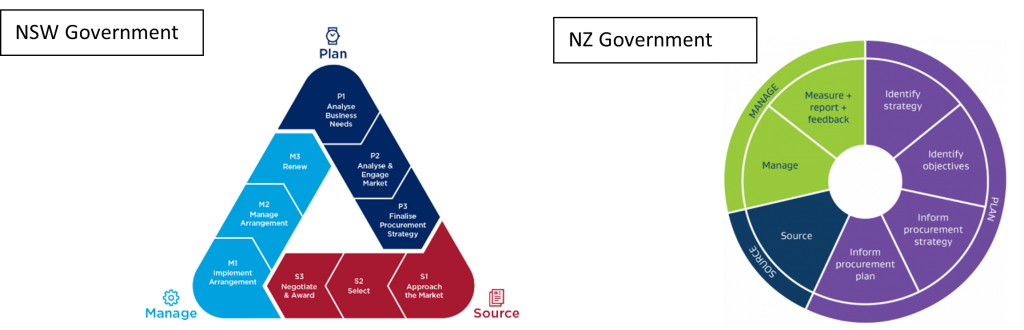

Think about the procurement process! At a high-level – Plan / Source / Manage

As a support function, Procurement rarely owns the budget and outcome of what is purchased. When discussing with stakeholders and budget holders about procuring a product or service delivering a customer outcome; how often even at the needs analysis stage does the stakeholder have their own ideas of who can deliver the outcome?

Similarly, when performing a market analysis how often does the stakeholder know the suppliers who could deliver the outcome?

Here is where you Influence POWER starts (especially if you know there are much better and/or new and innovative suppliers in the market than the ones offered up by a stakeholder).

In very technical fields senior technical leaders have gained their reputation based on their technical knowledge – knowledge built over the course of their working life.

How do you convince a senior engineer that company x (a name not recognised in the traditional market) can produce the highest quality outcome?

So, you have analysed the market, obtained all empirical data, and presented it to the stakeholders but the engineer says, “Over my dead body!” What do you do next?

The ability to Influence is again the POWER that you need to take this individual on the journey of change. You can only influence if you have Trust with your stakeholders and that is built on relationship and delivery. This exact scenario happened to me and it took over 3 years of coaching and influencing to get a great outcome for the organisation).

Evaluation will require the Influencing POWER. When I hear you say! At panel shortlisting when you can’t get a consensus.

What are your thoughts about this statement?

The Negotiation stage is about preparation and understanding your organisations BATNAs (Best Alternative To Negotiated Outcomes), However during the process there likely will be stages where you have to use the Influence POWER to obtain some of your desired outcomes.

Management and Performance usually comprising KPI measurements and monthly meetings will also highlight opportunities where a procurement professional will have to use their Influence POWER. Especially when asking the supplier to go the extra mile to sort out an issue.

There will also be instances when you meet with stakeholders using the performance data supplied to either commence performance management, reward the supplier, or start a new sourcing process.

Our profession along with most professions today need lots of these POWER Skills and there is always plenty of debate about the priority attributes.

I hope this has helped to simplify and provided some food for thought on what a complex issue this is and helps you think about the main attribute that you need to have as a procurement professional.

A question I will leave you with: If you have the POWER of Influence as a procurement professional, then why do you need a seat at the C suite table?

My views and opinions on this vast topic are part of a much wider industry dialogue – I’d love to hear your insights and feedback too.

If you are interested here is other reading on influence Power

https://hbr.org/2018/02/how-to-increase-your-influence-at-work

https://www.sciencedirect.com/science/article/abs/pii/S0278612516300589

You must be logged in to post a comment.